In 2009, a pair of bored college students had a truly bizarre idea that changed their lives forever. By 2011, that same duo, Nikhil Arora and Alejandro Velez, were diverting over 1 million lbs of used coffee away from landfills and right into their bank accounts. Over the next decade, the pair would use that coffee to make hundreds of millions of dollars, and even meet the President. Let's explore how coffee waste became president-approved mega-money and plunge into the unbelievable story of how these guys got rich in one of the most surprising ways ever.

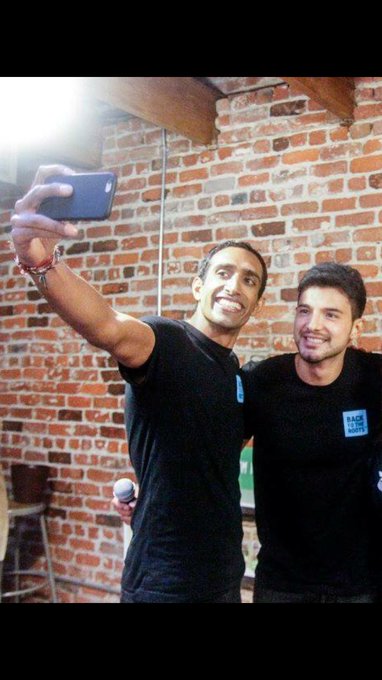

Back to the Roots: Nikhil Arora and Alejandro Velez

To fully understand how Nikhil and Alejandro’s solid gold idea made them rich, let’s first take a look at the serious problem that unexpectedly paved the road to their success, by generating huge demand for a solution. Every year, one third of the food on planet Earth is wasted. That’s a jaw-dropping 1.6 billion tons of edible food, worth a staggering $1 trillion, simply thrown out to rot.

What’s worse, if things continue as they are, research conducted by the Boston Consulting Group has estimated by 2030, those food-waste figures could soar, seeing as much as 66 tons of edible, usable food being wasted every second.

Considering the fact that starvation and malnutrition are still serious issues in many parts of the world, it’s easy to see the problem here. According to the Food and Agricultural Organization of the United Nations, all that

wasted food could feed a hungry populace equal to nearly 4 times the USA’s population every year, if we can figure out how to be smarter about the problem.

There’s another, major hidden problem with throwing away so much food, a problem that would ultimately fuel the enormous success of Alejandro and Nikhil. That major dilemma is all about the absolutely astronomical resources wasted in the production of food that exists purely to be thrown away. According to the smarty-pants data nerds at the Environmental Protection Agency, 5.9 trillion gallons of water, 778 million lbs of pesticides, 14 billion lbs of fertilizer, 170 million tons of greenhouse gasses, a behemoth 140,000,000 acres of land, constituting an area the size of California and New York combined, and enough energy to power more than 50 million American homes for a year are all used, or wasted, to

grow and transport this food.

All of which goes directly into the trash! And that doesn’t include the countless hours that humans, like you and me, spend making it all happen. It doesn’t end there though. Once wasted food reaches landfill, it starts to rot and release methane, with food waste, shockingly, leading to 8-to-10% of humanity’s greenhouse gas emissions.

Much like a meatball that’s fallen off our plate and rolled under the sofa, food waste has been ignored for a long time. But it’s in these very circumstances that our grand, unexpected money-making scheme begins to take shape. Let me ask you this: have you ever heard of something called upcycling? It’s a trendy word that gets a lot of lip service among eco-lovers and hipsters alike these days. But Nikhil Arora and Alejandro Velez, started upcycling food before it was cool, way back in the long-forgotten year of 2009. And it was the most lucrative decision they ever made.So what is upcycling? First, don’t worry, it’s not recycling. No one is reusing used food. Upcycling is when you repurpose edible food that would otherwise end up in a hole somewhere. So, like weird-shaped vegetables that some supermarkets don’t want, or the pulp matter left over after a juice company has squeezed their fruit and veggies dry. Products like this can be taken by an upcycling company, and be used to make other, perfectly-safe-to-consume products, like oils or chips. But what does any of this upcycling food nonsense have to do with making loads of dollar-dollar bills? California-born Nikhil Arora and Colombian-born Alejandro Velez were sitting in a business ethics class at The University of California, Berkeley, struggling to pay attention. Both already had job offers in investment banking and consulting, so they were pretty much set to go on and make some green in the big wide world.

They didn’t know each other at the time, but a single fact mentioned by their professor in that class would bring them together, change their lives, and lead them to make millions. That little factoid? Simply the idea that it’s possible to grow gourmet mushrooms out of spent coffee grounds. Most people would’ve heard that fact, thought it was cool, and moved on, but not these guys. Out of the 100 people in that class, they were the only two who approached their professor with a hunger to find out more about the concept, and the waste-to-wages business model it more broadly suggested. Their professor encouraged them to team up, to find out more about the enormous untapped potential lying dormant inside French presses and espresso machines the world over.The idea of using waste coffee to grow other useful stuff is likely almost as old as coffee-drinking itself. The earliest literary reference I can find, however, dates back to the mid-19th century. A

short article from an 1861 copy of the Alexandria Gazette, a Virginia-based newspaper that ran from 1834 to 1974, references how it’s already widely known that coffee grounds make a great fertilizer. Another early reference dates from seven years later, in an early November issue of the 1868 weekly magazine called “Once a Week”. The piece tells of a group of nuns who lived in a Naples convent. Every day, after eating, they would throw used coffee grounds into a shady corner of their garden. After some time, they noticed mushrooms growing from the coffee, specifically the Agaricus Neapolitanus.

Surprisingly, the mushrooms were found to be so delicious once cooked that, in many parts of Italy, it became a bit of a trend to collect used coffee grounds in a flower pot and then harvest the mushrooms every six months. Or at least it was a trend in 1868 when this was published. It’s clear that people have known about how coffee grounds are full of natural magic for quite some time.Of course, in reality, it’s not magic, but a cup full of science. Coffee grounds are full of all the good stuff plants and fungi need. Antioxidants, potassium, phosphorous, and nitrogen, come together to make coffee grounds an outrageously energetic fertilizer. But what makes coffee grounds so well-suited for mushroom growth in particular, is that the coffee grounds don’t need to be added to soil as fertilizer to grow mushrooms. Mushrooms actually don’t need soil to grow, and so can grow directly from the coffee grounds themselves, making for one killer team. The grounds merely have to be inoculated by adding a pre-established, living fungal culture, also known as mycelium, which is the root-like system that forms the core of any fungus. In a mere matter of days, the mycelium will grow throughout the coffee grounds, or other suitable substrate, and begin developing into harvestable mushrooms.

So, while the practice of growing mushrooms out of coffee has hardly been a secret, historically, very few folks ever connected the dots and saw the true potential for just how many dollar-dollar-bills could be made. Just imagine if modern farmers started using coffee on an industrial scale.

Not only would they get barely any sleep, but by dumping a load of spent coffee on their fields, they could achieve the growth boost of industrial chemical fertilizers in a much cheaper and more environmentally-friendly manner, while utilizing a widely-available waste resource. That’s where we get back to 2009. Nikhil and Alejandro decided to put the idea of up-cycling coffee to the test. They took over their fraternity kitchen and started running mushroom-growing experiments. They needed to know if it was actually possible to grow delicious mushrooms, repeatably, from old coffee. After nine failed experiments, they finally produced a batch of oyster mushrooms, so beautiful they’d make Mario proud.

It’s one thing to grow a mushroom, it’s another thing to sell one. They needed someone with the right gills to give their stamp of approval. They approached one of the two head chefs at Berkeley’s Chez Panisse, the best restaurant in town. After, after what was quite literally a trial by fire, sautéing and eating one, the master chef enthusiastically endorsed their idea. The mushrooms were delicious.A short while later, after word of their successful investigations began to spread, the students received a $5,000 grant from the Berkeley Chancellor, and turned down their previous job offers, choosing to become full-time urban mushroom farmers. And so, their company,

Back To The Roots was born. Within six months they sold 3 pounds of mushrooms to Berkeley Whole Foods and by 2011, they were upcycling over 1,000,000 pounds of coffee a year. By the end of 2012, that number had increased to 3,600,000 pounds of coffee, and they were selling 500 pounds of oyster mushrooms every week, to customers across the whole of Northern California. That’s about three beer kegs full of oyster mushrooms by the way, just to put things back into college student terms.

If you’re not into mushrooms and don’t know how much these things cost; at 2024’s prices, a five-pound carton of oyster mushrooms is about $30. So 500 pounds comes to $3,000 a week, or $156,000 a year. And given that, by this time, Back to the Roots’ business had diversified to selling a wide range of other sustainable products too, it’s clear their venture was going amazingly well. Not bad for two college grads, right?

Given that 60 million tons of coffee grounds are trashed every year, equal in weight to 10 of the Great Pyramid of Giza, they had plenty of raw material to expand with. I guess you could say the world was their oyster mushroom.And it turned out, people loved the idea of growing mushrooms from upcycled coffee. So, the duo started selling "Mushroom Grow Kits" of inoculated substrates, biting off a slice of the gardening consumables market; a market expected to grow to $22 billion by 2030. In 2012, they’d made such a splash that they were invited to the White House, in recognition of their innovative success story.

Within a few more years, they had stopped farming and selling fully-grown mushrooms altogether, finding their inoculated coffee-ground grow kits to be much more profitable. It was certainly the right call. Between 2019 and 2020, they saw a 300% growth in sales revenue, and closed the 2023 gardening season by earning the title of America’s fastest-growing organic gardening brand. According to the U.S Chamber of Commerce, Back to the Roots was expected to turn over more than $100 million in 2023. While, unfortunately, their official earnings are private so we can’t confirm these figures as of 2024, what we can confirm is how much they’re raking in from investors. According to the records of the United States Securities and Exchange Commission, in 2022, Back to the Roots secured $18 million worth of investment in venture capital funding. A year before, in 2021, they raised $15 million, and as of 2024, they’ve raised a total of almost $37 million total from investors since their inception in 2009. So while their exact turnover isn’t public record, if they’ve drawn in nearly $40 million from investors, they’re clearly doing something right, and it’s pretty clear there’s a market for those who want to help reduce the world’s extreme food-waste issue with upcycled goods.

Today, Nikhil and Alejandro have witnessed their company grow into something beyond their wildest imagination. Aside from the monetary success, they’ve also donated tons of grow kits for educational purposes to elementary schools; expanded their product line to include organic seeds, gardening kits, and live plants;

partnered with Fortnite; and upcycled millions of pounds worth of coffee.

Interestingly enough, they don’t actually use upcycled coffee as their primary substrate source anymore, and typically use another, equally widely-available waste resource, sawdust, for their mushroom kit substrates nowadays. It’s still undoubtedly a fantastic usage of industrial waste products, and the commitment of Back to the Roots to sustainability and upcycling looks like it has inspired other companies to follow suit.

Back to the Roots Organic Mushroom Kit (how it's made) by Back to the Roots Upcycling Trend

Recently, German supermarket chain and one of the leading food retailers in Europe, LIDL, has partnered with a revolutionary egg farm that upcycles. Kipster Egg farms, otherwise known as the “Farm that gives a cluck”, operate out of the Netherlands and the United States. Their chickens are fed using by-products from crop and food processing, like faulty pasta, or unwanted pastries and bread.

This partnership, utilizing pre-existing wasted foodstuff, will reportedly result in Lidl cutting their chicken-feed carbon footprint by up to 60% if fully rolled out across their network, being much more eco-friendly than growing new grain specifically to feed chickens with. But while the chickens are living it up, eating pasta and pastries, us humans are going in the other direction and are starting to eat trash.This peculiar fact is all thanks to a chip brand by the name of

Trashy. This American company turns old and unwanted vegetable scraps into new fiber-rich, gluten-free vegan chips. The vegetable ingredients start their life at various Los Angeles juice companies. From these spots, tens of thousands of lbs of pressed, waste vegetable pulp is collected, post-juicing, each time Trashy’s collection teams visit. Then, they magically turn it into chips.

Well, probably not using magic, but they haven’t revealed their exact process. Most likely, the process involves pressing the pulp into flat sheets, cutting it into suitable sized pieces, dehydrating or baking the pieces, and adding flavoring. What they don’t keep a secret though, is that they save 38 gallons of water going to waste per pound of pulp, which would usually be simply discarded. Better yet, anything Trashy doesn’t end up using, goes on to become animal feed. From 2020 to February 2024, they saved over 170,000 pounds of vegetables from going to waste. It’s a good start but we’ll still need a lot more to make up for the 1.6 billion tons of food waste each year.So, when it comes to wide-scale upcycling, it’s all about thinking outside the box. And that’s exactly what this next company did.

Gumshoe is a new type of sneaker made from chewing gum. The sneakers are made from

Gum-Tec, a compound known as a thermoplastic elastomer, that’s 20 to 30% chewing gum mixed in with other plastic-rubber compounds that can be melted down and shaped into usable forms.

Gumdrop, the company that makes them, sneaks around the aesthetic streets of Amsterdam scraping up all the discarded gum they can find, which is a lot. Every year, a huge 3.3 million pounds of gum are dropped on the streets there, and for every 2.2 pounds of gum they collect, four pairs of sneakers can be made.Recently, they partnered with Adidas to make five new styles of Gum-tec shoes. They’ve also expanded into making coffee mugs and their own Gumdrop trash cans, each made of 166 pieces of gum. The trash can is for gum only; gum which will be used to make more gum-trash cans! Then, once the Gumdrop trash cans reach the end of their life cycle, they’re recycled to make even more Gumdrop trash cans. And so goes the circle of gum life.

While this sounds like it’s great for the planet, it’s also good for the Benjamins. Gumdrop claims that these bins collectively save their clients $1.25 million a year on cleaning bills. I’m not sure about you, but those clients must have one hell of a gum problem. If Gumdrop keeps innovating at this rate, we’re not going to be asking if objects are secretly made of cake anymore, but if they’re chewing gum! So, by now it’s pretty clear that there’s money to be made in finding a purpose for seemingly-useless waste products. So much so, the food upcycling market is expected to reach $97 billion by 2031. And while we’ve covered some fascinating stuff so far, what we haven’t mentioned yet might be the most mind-blowing, and widely-useful food innovation ever. Because it turns out, waste food can be used to make energy!

The waste-to-energy model uses

anaerobic digestion, or A.D. for short. This amazing technology converts agricultural waste into usable energy. The system works by collecting plant and animal materials, like waste foods, feed, manure, and other organic farm stuff, and locking them inside a sealed tank, or to use the technical term, a digester. Once sealed inside the airless container, anaerobic means airless by the way, the material begins to rot, thanks to specialized bacteria and fungus. As it does, it releases gas which can then be used as fuel to generate electricity and heat.

As farmers increasingly use electric-powered tools and vehicles, the production of biogas, on-site, means they could in theory power the whole farm, including their tools and vehicles, on their own waste-products, allowing farms to drastically reduce their greenhouse gas emissions.A by-product of these systems is what the science people call digestate. Once all the organic material, inside the digester, has rotted away, what’s left is a nutrient-rich fertilizer; ready to make its way back to the crop fields. Scientists are even finding alternative uses for this digestate, for example, a blend of digestate oil, biodiesel, and alcohol, has been found viable as a fuel for cars. The studies are looking pretty promising too, so who knows, maybe we’ll be upcycling food right into our gas tanks in the near future. Right now, an A.D. system costs between $625,000 and $6,250,000 depending on the size of the farm, so while they’re not cheap, their potential is huge.

The idea isn’t actually anything new. The United Kingdom has been using anaerobic digestion systems since the 19th century. In 1895, the idea to divert biogas from the sewers to fuel the gas street lamps was introduced. Biogas is still used in the UK today, and while it doesn’t fuel their street lamps, currently, 500 A.D. systems collectively generate 3% of the county’s total renewable energy.

Unfortunately, the current downside is that these systems can be costly to set up compared to just buying other types of fuel, can take a lot of work to maintain, and are fairly inefficient, but here’s hoping for a future fueled by farm waste, and these magical fart collection chambers. What about us normal folks who don’t have access to industrial machinery, who might still want to upcycle food waste to save money and earn cash? Don’t worry, there are alternative ways.Upcycling used tea, of all things, is a great way to give your plants a new lease on life, and more significantly, make a healthy profit. Since tea leaves are full of nitrogen, they make ideal fertilizers. Plus, since tea is very popular, and there’s an abundance of cafes throwing out the spent leaves, there’s a huge opportunity to capitalize on this waste product. Something which China-based company,

Chazence is already doing! Chazence upcycles waste tea leaves into plastic! Or, at least tea fiber plastic, a patent-pending material that can be used for products ranging from tableware and cups, to bags. The ingenious approach involves breaking down dehydrated, leftover tea leaves into powder, before mixing them with tea oil and plant-based plastics. The result is a surprisingly versatile material that actually retains some of the tea leaves’ natural fragrance and color.

But if tea isn’t your thing then how about bananas? Banana peels are a great product to upcycle. They’re full of potassium, fiber, protein vitamin B6, vitamin B12, and magnesium, all of the good stuff plants love. If you dry a peel, and grind it up, you can sprinkle it on plants as a fertilizer. Alternatively, if you wrap a peel around the base of a tomato plant, it likewise helps the plant grow. Amazingly, you can also use blended-up banana peels with a dash of water as ultra-cheap polish paste, for shoes and tarnished silver alike, as the natural oils and gentle abrasive properties act in a somewhat similar way to regular polish products. There’s actually already a pretty successful company that upcycles bananas, called Barnana, who’ve built a multi-million-dollar business from taking bananas deemed too imperfect for consumers, and turning them into

healthy, dehydrated banana snacks.

Countless start-ups are doing their best to tackle food waste and governments are also starting to move in a similar direction. In 2015, the US government introduced an ambitious goal to reduce food waste by 50% by 2030, with schemes to invest in tech innovations, education, and recycling.

Meanwhile, countries like South Korea banned food waste, outright, way back in 2005. South Koreans pay a small food waste tax for anything they don’t use. The tax is only roughly six cents per two pounds of waste, so it’s not a lot. It did, however, lead to a welcome 20% reduction in home food waste, a 5% reduction in groceries bought, and has saved the average household $172 a year.While there’s no doubt we’ve got a long way to go as a species to

tackle all the food waste on Earth, what’s becoming increasingly clear is that, not only are there obvious environmental benefits to doing so, but there’s actually real money to be made. All it takes is the outside-the-box thinking of clever individuals like Nikhil Arora and Alejandro Velez, taking stuff that’s going to waste anyway and finding ingenious new ways to utilize it. I hope you were amazed at the story of Nikhil Arora and Alejandro Velez alongside successful stories of upcycling! Thanks for reading!