Largest Things Ever Moved

January 13, 2025

•19 min read

These are the largest things that have ever been moved!

It’s safe to say us humans are obsessed with constructing some massive megastructures. But, big and impressive as those feats of engineering ingenuity are, have you ever considered how they got there in the first place? Even more impressive than the size of some structures, are the tremendous transport operations that helped them get from A to B. From towing towering oil platforms, to road-ready space shuttles, let's explore some of the largest things ever moved!

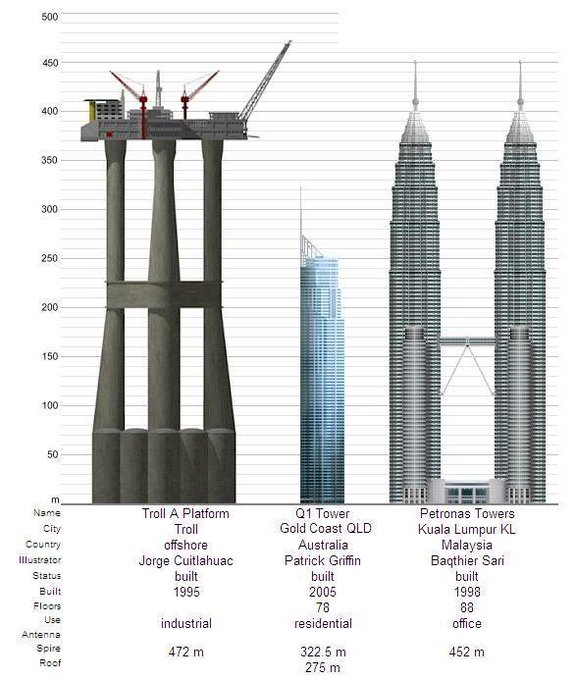

Troll A Platform

At 1,549 feet tall, the Troll A platform, found in the middle of the North Sea, is a super soaring structure. In all, that platform, used to extract natural gas from the Troll gas field, measures around the height of the Central Park Tower, the 15th tallest building in the world!

That platform is mostly made up of four legs descending down nearly 1,000 feet to the sea floor. The question is, how did something so big end up there? That behemoth was constructed in a dock near the village of Vats on the western coast of Norway. After the legs had finished construction, they were filled with water until they were virtually submerged. Following that, engineers towed Troll A’s platform over the legs. Once the platform was floating above the legs, the water was pumped out of the legs, gradually raising them out of the water and closer to the platform overhead. After all that, by May 1995, Troll A was finally ready for its journey. Now those involved had the small task of getting the 1.2 million ton structure from Vats to the Troll gas field over 120 miles away! Ten tugboats had the unenviable task of towing the towering structure.Located about 80 km off the west coast of Norway is ‘Troll A’. A colossal natural gas platform and the tallest structure ever moved by mankind. 472m high, weighing 656000 tons. Engineering masterpiece.

The Endeavour Space Shuttle

When you think of space shuttles, you probably conjure up images of rockets whizzing through orbit. But that’s not always how those vehicles get from A to B. Take the Endeavour, for example. From 1992 to 2011, the shuttle completed 25 missions, visiting faraway locations like the International Space Station and the Hubble Space Telescope.

Yet, the Endeavour’s final journey wasn’t quite so meteoric. Rather than paying one last visit to space, that rocket had to make the 9 mile journey from LAX airport to the California Science Center. Sounds simpler than flying into space, right? However, weighing in at 86 tons, the shuttle was too heavy for a helicopter, plus it couldn’t be dismantled without causing permanent damage to the vehicle. So, the California Science Center made the decision to shell out $10 million to transport the shuttle overland.That came with another problem, though. At 122 feet long, and 78 feet wide, the Endeavour wasn’t exactly road ready. Being so long and wide, there are a whole host of paths in Los Angeles that the Space Shuttle could never realistically travel through. Eventually, a 12 mile path was settled upon, with the Endeavour taking off at midnight on October 11th 2012.JJ Whale

But it’s not just enormous inanimate objects, like space shuttles and oil platforms that have been part of mega moves. Back in January 1997, a week-old female gray whale was found stranded on the coast of southern California. To save the critter, it was decided she’d be brought in to SeaWorld San Diego to undergo rehabilitation.

A crowd of seagoers hoisted the 14 foot-long, 1,670 pound-heavy young whale onto a 24-foot truck, constantly dousing her in water to keep her hydrated. Following a lengthy 140-mile journey, the creature finally reached SeaWorld San Diego.

Heat Recovery Steam Generator

In 2017, McLaren Engineering Group embarked on their own trepidatious transport mission. They were tasked with moving a Heat Recovery Steam Generator, or HRSG for short. That is a pretty important piece of kit in power plants, used to capture waste heat from gas turbines. The generator McLaren moved was a neck-breaking 130-feet tall, and weighed some 4,000 tons!

Essentially, that cargo was close in height to the Arc de Triomphe and around as heavy as 70 standard American homes! On top of that, McLaren Engineering Group had to somehow transport that thing down 130 miles, from Ravena, New York, to a power plant in Sewaren, New Jersey.Unsurprisingly, it was ruled that the colossal cargo was too tall to make the trip on land. Instead, it was decided the best route would be down the Hudson River. So, a fleet of five Self-Propelled Modular Trailers delivered the HRSG onto a 400-foot long barge, which would be towed by three tugboats.The Statue Of Liberty

Whether it’s the Empire State Building, One World Trade Center, or the Statue of Liberty, New York has some of the world’s most recognizable attractions dominating its skyline. But while the Empire State Building and One World Trade Center were constructed in the Big Apple, the same can’t be said for lady Liberty.

Abu Simbel Complex

But the Statue of Liberty isn’t the only bulky bust to have undergone a major move. Back in 13th century BC Egypt, Pharaoh Ramesses II oversaw the construction of the Abu Simbel complex. Carved into the cliff face were two massive temples, as well as four colossal statues of Ramesses the second, with the entire structure stretching 125 feet wide and 108 feet high!

That monumental marvel stood strong for more than 3,000 years, until in the 1960s plans to construct the Aswan High Dam right next to the structure threatened its very existence. Numerous ideas on how to save the temples were put forward.One involved building a gigantic aquarium around the temples with elevator-accessible underwater viewing chambers for visitors. Cool as that’d look, the idea was way too ambitious to get the green light. Another proposal involved raising the temples on hydraulic jacks, but the cost would’ve been immense.Rocky Road

In the 1760s, work began on the construction of The Bronze Horseman, a statue that was to be erected in St. Petersburg. For the pedestal, it was decided the Thunder Stone, a large boulder found in the marshland of Lakhta, would be used. The only problem was that Laktha is around 4 miles away from St. Petersburg.

While cranes and trucks were used to help with the transportation of Abu Simbel, that sort of technology wasn’t around in the 1700s. Instead, they had to rely on good old manpower. Considering that big boulder was 46 feet long, 16 feet high and weighed over 1,600 tons, that was no walk in the park. 400 men were given the tough task of somehow moving the stone.CC-177 Globemaster III

Stretching to a length of 174 feet, and weighing in at 208 tons, the CC-177 Globemaster III aircraft is virtually twice the length, and equal in weight to a blue whale! While it’s nowhere near as heavy as the Thunder Stone, what makes the moving of that aircraft so incredible is who did it!

Back in 2009, one lone individual attempted to move the CC-177 Globemaster by themself! The plane puller was Kevin Fast, a pastor at St Paul’s Lutheran Church in Canada. The plane was secured to a rope attached to Fast’s body, while the pastor pulled at a thick rope to edge himself and the colossal cargo forward.Incredibly, after heaving the haul for 76 seconds, Fast somehow managed to lug the 200-plus ton load close to 30 feet! Just thinking about Kev’s formidable feat is making me sweat. The only thing stronger than that pastor’s faith in God are his calves!Relocated Building

If you’ve ever moved home, you’ll know how stressful the process of lugging all your belongings from place to place is. Still, that’s way more chill than one house move that took place in Wuhan, China, back in 2016, where the building itself was moved! In fact, that wasn’t even a house, it was the Hankou Yiyong Fire Association, a huge three-story building, reaching 111 feet tall, and weighing in at a staggering 16,650 tons!

Templos y otros monumentos son transferidos de un sitio a otro en China gracias a esta tecnología cnn.it/2nk58TT

Splitter Vessel

A giant splitter vessel is a large piece of industrial equipment used in the petrochemical industry to help the refining process of oil and gas. The splitter below measures out at 315 feet long and weighs over 800 tons. For reference, that thing is equal in length to 18 limousines, and as heavy as four Boeing 747-400s!

MV Sewol Ferry

In April 2014, the MV Sewol, a passenger ferry travelling to South Korea’s Jeju Island, tragically capsized after making a sharp turn while battling a strong current. 3 years after the disaster, attempts were finally made to salvage the wreck. At the time of its capsizing, the vast vessel weighed over 6,800 tons, and was carrying over 3,600 tons of cargo.

As you can imagine, lifting nearly 10,000 tons of weight from the sea is not easy. To start with, two huge barges were placed either side of the wreck. Beams were then installed below the ship by digging through the seabed underneath. From there, cables were attached to a hydraulic jack system on the barges that pulled the sideways ship to the surface.Liftboat

We couldn’t mention sea-based super movers without giving a mention to boats that elevate themselves out the water! It's all down to an ingenious invention, known as a liftboat. At sea those boats float on the water like any other. However, they’re also equipped with three or four long limbs, known as pipe legs, which can extend down 220 feet deep into water.

The legs are controlled using a jacking system which lowers them to the sea floor, where they can be securely attached, either on a pre-built platform or by penetrating into the ground. As well as that, those legs can be retracted and extended vertically, meaning the ship’s hull that was once on the water’s surface can be elevated to a heady height.

Bullwinkle

Found in the Gulf of Mexico, a humungous oil platform, known as the Bullwinkle, stands over 380 feet over the waves. Below the water, that super structure dives down a mega 1,353 feet, meaning the total length of the Bullwinkle oil platform exceeds 1,700 feet. That makes old Bully about as tall as the One World Trade Center!

But, how could something so mega get transported to the middle of the Gulf of Mexico? First, we’ve gotta go back to 1989. That was the year construction of the platform had finished in Texas. By the time the jacket of the Bullwinkle was complete, it weighed around 50,000 tons around 7 times the mass of the Eiffel Tower’s frame! After construction was complete came the hard bit, moving the thing!Concrete Cargo

In the Jeanne D’Arc Basin, over 2,500 miles northeast of the bulky Bullwinkle, is the site of another colossal construct. For example, The Hebron Gravity-Based Structure. The Hebron oil field, located off the coast of Newfoundland, Canada, required the construction and transportation of a colossal gravity-based structure otherwise known as GBS, to extract oil Gravity-based structures get their name from the fact that they’re anchored to the seafloor by their tremendous weight, and this particular concrete behemoth would provide stability for the oil platform above.

After construction of the Hebron GBS was completed in a dry dock, the structure reached a heady height of 390 feet. On top of that, Hebron GBS also consists of over 4.5 million cubic feet of concrete, enough to fill more than 50 Olympic swimming pools, meaning that titan clocks the scales at over 650,000 tons.Al Majdouie's Water Desalination Unit

In January 2012, land transport company, Almajdouie, embarked on the most ambitious terrestrial transport operation ever attempted. They were tasked with moving a water desalination unit, a facility that turns saltwater into drinking water. But that wasn’t any old water desalination unit. In total the unit measures over 400 feet long, 110 feet wide and 40 feet high, making it similar in size to a football field!

If that didn’t sound massive enough, the unit also weighs a backbreaking 5,400 tons! A 475-foot vessel transported the unit overseas from South Korea to a port of Ras Al-Khair, in northeastern Saudi Arabia. From there an SPMT, equipped with 172 axles, 688 double-width tires and a load capacity exceeding 7,300 tons was placed under the unit. After slowly rolling the structure of the boat, the SPMT now had the arduous task of transporting the large load from the port to the Ras Al-Khair Desalination Plant over 4 miles away.